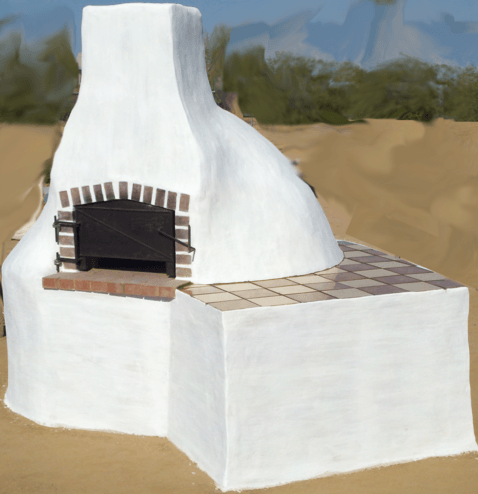

Well my day started out good. I was sore and stiff from working on the oven for the last few days but, I was excited to start working on the tile for the counter. Laying this tile represents hitting the home stretch on this oven. Wow, was I in for a surprise.

So I begin by getting out my terra cotta tile and laying them out on the counter. The first thought that ran through my head was “Oh Crap!”. It turns out that in adding the bricks and filling all of the gaps I had inadvertently nearly doubled the square footage of the counter and I now only had about half of the terra cotta tiles that I needed. So much for my good mood.

Ah, I have an idea. Our friends Rick and Bridget were cleaning out their shed and they found some stacks of old used tile. They donated the tile for our project. I was originally thinking of using the tile to cover a table but, this could be a solution for me.

After playing around with different patterns and pieces I had found enough tile to use but, before I could use the tile I had to scrape all of the old mortar off of the tiles. Once that was done I began laying out the tiles on the counter.

So these are my basic tools that I was starting out with. Now had I been working with the terrra cotta (also known as salatilo) tile the tools would have been fine. Terra cotta is made from earthen clay and so is not fire at extremely high temperatures. This makes the tiles softer and easy to mark, score and leave a clean break. All that needs to be done is to use a sanding attachment to finish smoothing the edge.

Well I’m here to tell you that porcelain tile is an entirely different animal. It turns out that porcelain has other components besides clay and is fired at much higher temperatures. This makes the porcelain much harder than the terra cotta and I found this out the hard way. As I had planned to cut the terra cotta by hand I didn’t have access to a wet saw or tile saw, man that would have been nice.

So on I went aligning all the tiles and marking them to cut. I thought the heavy duty cutoff discs that I had would work. Boy was I wrong. The cutoff discs wore down before I could cut 1 tile. So I said OK lets just try and score the tiles and break them along the score. Well this sort of worked but, it took a lot of work. I thought about it and decided to try a hand grinder to make the cuts. Wow that was a monster fail. The tile barely got cut and the grinder disc started to heat up bad and wear down fast. OK on to the next idea.

I have a Dremel Multi Max oscillating tool that I had used before so I figured why not I could try it. I put on the diamond tipped grout blade hoping the would last. Well it worked but, man did it cut slow and after cutting a couple of tiles my bad wrist was killing me. So there I was cutting away like crazy when I realized that I was going to have to round some of the cuts to make things fit right. Well how can I do that with this tile? I figured out to get the largest pliers that I had and to use them like nibblers. This actually worked really good to remove a small amount of material at a time but, it was really slow and hard on my wrist and shoulder.