Alright so we discussed how I came up with the air gap in the door as well as how I built the door. This was the easy part. Now I had to figure out how to hang the door and since this outer door came about as an after thought this presented some problems. I found that the people that did design their ovens to have an outer door usually had a metal arch insert that the door hung on. Well my problem here was that to use the insert I would have had to build it in as a permanent part of the oven and I didn’t. So time to be creative.

I had to figure out how to distribute the weight of the door fairly evenly around the dome of the oven and how to mount the door to the oven. Well I looked at what I had and figured that I could use the rebar and wrap a couple of rings around the oven and support them. Then I figured I could encase the rebar inside the oven between the thermal and insulative layers. Well that was my plan any way.

So The following pictures is what I came up with as my solution.

So this is is my initial frame work. I used the 3/8 inch rebar and wrapped one strand around the lower end of the oven and a second strand about mid level. I used an arch of the rebar just behind the chimney and one piece from the chimney over the back of the oven. I welded all the connection points so the frame was rigid enough to support and distribute all of the shifting weight of the door and keep the lock steady.

OK I guess that I should tell you how I setup the the hinges. This was one hell of an experience. The first thing I did was to grab my propane torch, a vise and a small sledge hammer. I figured that I could heat up the rebar clamped in the vise with the torch and hammer it into shape. Yeah right, that worked about as well as a hole in the bottom of a glass. After heating with the torch and about a dozen hammer blows the end that I was trying to bend snapped off and my shoulder was killing me.

A new plan was needed. I had to figure out how to heat the rebar enough to soften it so I could bend it without aggravating my injuries any more. OK here was where the light bulb went off, I have an oven that gets really hot. So I built a good hot fire and used the oven as a forge. Talk about a three ring circus. So here I have two 20 feet long pieces of rebar that I have to get into the fire to heat up. Well I have my sons Jason and Charles holding the piece of rebar at one end and the middle. That way they can hold it and move it while I guide it to where I need it to be.

So we get the first piece in and start heating it. When I saw that it had gone past red hot and started to go orange I figured now is the time. So I had the boys pull out the rebar and swing the end around so that I can clear the corner of the house and get to the vise that is sitting on the counter area. After about four times of trying to line things up, because teenage boys never stop moving, we got it in the vise. After about four soft hits with the hammer I had about a 90 degree bend but, it started to cool down to much to continue so we did the dance to get it back into the fire. After letting it heat back up we pulled it out and danced around again to get it lined up. This time I was able to use the vise it’s self crimp back the end the rest of the way making a nice loop on the end of the rebar. We set the first piece aside to cool and repeated the entire process a second time. It really was a good show and by heating the rebar in the oven it saved my shoulder immensely.

So this is a picture of how my hinge loops turned out. Also just a quick note on their alignment. I used a piece of 1/2 inch rebar that I checked with a level for plumb, that’s straight up and down not the fruit, before I welded all of the frame together in order to make sure that the door would hand level and even. OK so it was a good and ready to hang the door. Now I had to figure out the rest of my hinges.

I used the 1/2 inch rebar I had left for the hinges. As you can see in the picture above I offset the hinge so the door would sit into the the arch about 1/2 inch. I used the 1/2 inch rebar for the hinge so it would be stable and not flex when the door was open.

As you can see in this picture I made the vertical ends of the hinge in two pieces. I did this so that in the future I could remove the door.

In this picture you can see that I used three flat washers in order to align the door. The first washer I welded on to the vertical part of the hinge so there was a flat smooth surface to rotate on. The other two washers I welded on the top and bottom of the hinge loop, but before I welded them I used four wedges to align the door and setup all of my spacing. I used the the flat washers on the hinge loop to lock my alignment in place and provide a bottom flat smooth surface for the hinge.

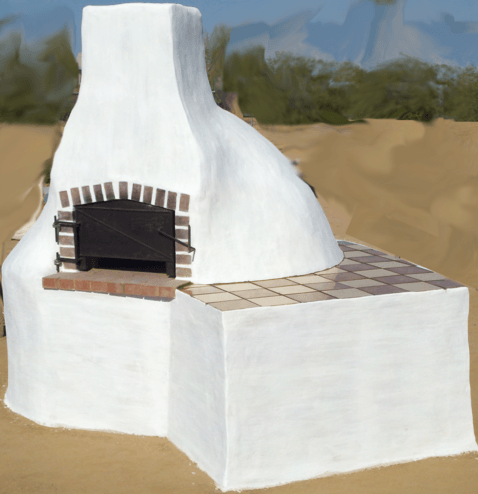

One quick note to add here was that after I hung the door I had to stiffen and support the hinge side a little bit more. You can see the extra rebar that I added in the picture before the last. The added stiffness stopped the twisting and the support that goes to the ground stopped the bouncing when I would open the door. All of the supports will be encased inside the rest of the outer layers of the oven and base so none of it will be seen when it’s done.