The thermal layer is the layer that makes your oven work. I read that same line over and over again as I was doing my research. I kept trying to figure out exactly what this meant. To put it simply it means this layer is the oven. The insulation layer helps hold the heat and the outer layer seals and waterproofs everything but, the thermal layer is actually the working part of the oven. This layer is central to the entire oven project. It will be the layer that holds and radiates the heat of the oven. This layer will also be a monolithic dome that will be the structural support for everything else on the oven.

Due to the exposure of fire and extreme heat I chose to build the thermal layer with no straw. This is essentially the same mix as a clay brick or terra cotta. Remember the mix is 2:1, two parts sand and one part clay. I settled on this mix with no straw because when I made a test ball with some straw and fired it in the barbecue it was weak and crumbled but, the one with no straw was hard as a rock. I wanted the strength in the dome.

I know all this sounds strange but, after you put down the first couple of rows you’ll get the hang of it. A technique that I used was to place the cob with my left hand while pressing and shaping at the same time with my right hand. This technique also allowed me to keep the thickness consistent. I had to measure the width of my left hand to determine where to hold my right hand. This seems a little awkward at first but, I got used to it very fast.

So when the sand form is all completely covered and you are happy with it then you need to give it some time to set. This was tough to judge since the cob seems to set and solidify in no time at all and because it took us two days to build the thermal layer since we ran out of sand. Once the thermal layer is set then on to the next step.

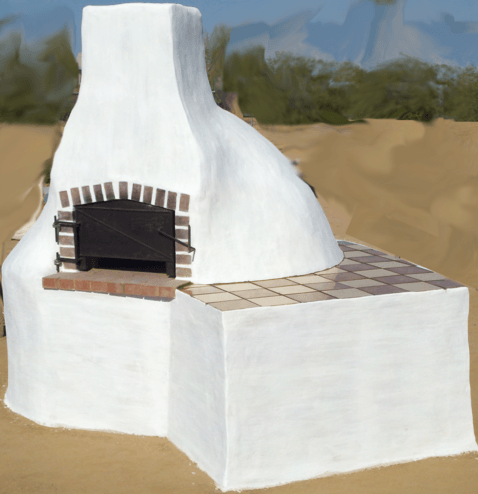

One side note here is that when we began building the thermal layer I very quickly realized that the brick risers that I had planned to build as part of the arch would have to be put in as the thermal layer went up. I didn’t have enough room on the base where I was putting the door. So I had to include the first six layers of the risers. My risers were mortared together with the same cob mix as the thermal layer. This also embedded the risers into the thermal layer which made them very solid.