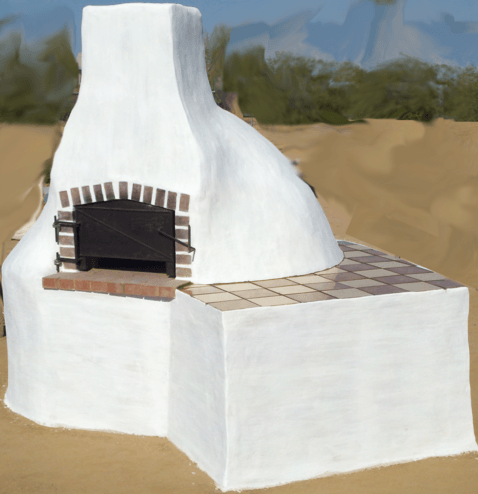

Well the plan was to whitewash on Monday with coat number 4. Yeah that didn’t happen. Just too many things to do and more rain. So by Thursday I finally got a chance to put on coat 4 and followed up on Friday with coat 5.

As you can see in the picture above the whitewash is really gotten brighter and evened out. I really wanted the last coasts on so if I had to make any repairs after using the oven on Saturday I could. Saturday we had some family here plus we invited some friends out to make pizzas.

This oven cooks pizza amazingly well! We make up a very large batch of pizza dough and then cut it down into dough balls for each person with sometimes a few extra and a large pot of pizza sauce. We split up the toppings so everybody brings a few. This way there is plenty for everyone and everyone can make their own pizza.