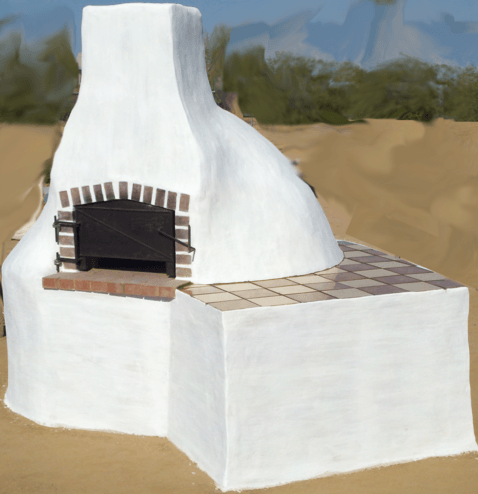

While we left the thermal layer to cure I decided to finish cutting the door before the cob got any harder. I had made a frame for the arch in order to support the bricks while I was laying them. I made sure that the outer arch was about two inches taller than the height of the oven door. I measured out centered and marked the final height of the door on the oven. The I used the arch template to mark my curve of the oven door. Then I decided I wanted a one inch reveal of the oven door. OK I know more fancy words. The reveal is the part of the door the you see that sticks out past the bricks. It looks like a frame that is visible inside the frame of the bricks.

I built the frame with a 2×4 base and 1×2 risers and arch. In order to get a nice smooth curve I made kerf cuts 1/4 inch apart 1/2 inch deep with a table saw. Then I nailed the arch to the center riser and then the end risers. I also ran the outer risers along the blade of the table saw to cut the ends of the arch smooth and in line with the outer risers. This technique created the template, curve and corners beautifully. However I ran into a small problem when I used the form to make the arch. This form needs more support than only the center riser. As you can see in the picture below the weight of the bricks flattened out the sides of the curve. So I would recommend adding one or even two more risers on each side.