First off let me say that since I applied the original whitewash in August and September of 2011 we have had some very unusually wet, cold and windy weather. Over the last 18 months we had wind storms with wind speeds measured up to 125 miles an hour, we’ve set cold temperature records and even set some rainfall records. Basically our weather has been much different and harsher than we’ve been used to.

I’m making a special point about the weather we’ve had and the time period because, the weekend following my post “Lessons In Lime” on June 11, 2012 is when I reinjured my back and hip. So I never had a chance to apply the lime stucco as I had planned. That means the only whitewash that was on the oven was the original coats from August and September of 2011 and the added coat in March 2012.

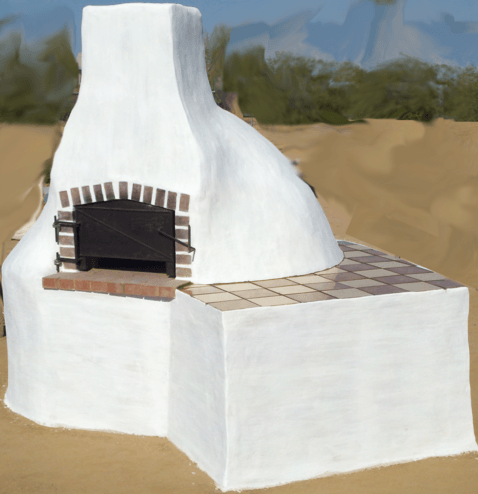

You can see that there is still whitewash on the oven. Surprisingly it actually has lasted and the areas where the whitewash bonded well is still protected well. I tried to use some tarps over the last 18 months to help protect the oven from the weather but, I’m not sure how much good the tarps are doing. Everywhere the tarps were in contact with the whitewash is where the whitewash is gone. There was also other physical damage caused by the tarps flapping and hitting the oven. Also there was damage from the cords, wood and blocks that we used to hold down the tarps.

There was also some cracking on the dome and chimney but, I know that 99% of that was from heat expansion. We’ve have been using this oven regularly over the last 18 months and at one point we really put it through it’s paces. We decided to really stoke the oven. Wow did it get hot!

Ok, so here is where the guy thing comes in. We wanted to see just how hot it was. Now I know that the carbon is burnt off at about 900 F and there was absolutely no carbon in the oven. So we already knew that we were over that. So I had the bright idea to try and place a glass bottle in the oven to see if it would melt. I know that glass softens at about 1700 F to 1900 F and melts at about 2600 F to 2900 F. I figured I could use the bottle as a rough temperature estimate. Well that worked but, the bottle melted. It didn’t just soften and slump down, I mean it melted and puddled. I used a poker to try to move it and it was glowing red hot, soft and even sticky. It wanted to stick to the end of the poker and stretch. So I know that the oven got really hot from that and I saw some of the cracks develop that night. On the plus side I can say that it took over 48 hours for the oven to cool down. The oven held the heat amazingly well. Truthfully this little experiment really showed just how hot this oven can get and how well it can hold heat. The downside of the experiment were the expansion cracks on the dome. The cracks are easy to fix though.

The most amount of damage was caused by the water running off of the counter. It seems that when the water would run over the edge of the tile it would get pulled to the wall by the surface tension and undercut the tile edged. Truthfully this is the most amount of damage on the entire oven. The oven looks worse than it really is from all of the whitewash being flaked off.

Overall I have to say that the oven has weathered very well over the last 18 months. Even with all of the freak, unusual and extreme weather that we have had during this time. I am planning on adding the lime stucco to the oven and a roof covering. Hopefully I can get both done this year. Based on the last 18 months if I did nothing to the oven and just left it as is, I could get several worry free years of use out of it. However after that it would need lots of work. With just a coating or two of whitewash a year I really think the life of the oven could be extended for many years. The same would hold true for the lime stucco coating. This oven if maintained could last for as long as I do, which is what I am planning on.